February 17, 2021

Making Crémant de Bourgogne , Visit Veuve Ambal

Steps in the Crémant de Bourgogne production process. Guided tour of the Veuve Ambal production site, the first producer of Crémant de Bourgogne.

Presses and winery.

Hand-picking is compulsory. The grapes are pressed, then each variety (pinot noir, chardonnay, gamay and aligoté) is vinified independently to obtain the “base wines”. Our oenologists create “cuvées” by blending these basic wines, to which they add the “liqueur de tirage” composed of wine, sugar and yeast.

Special assemblies :

Blanc de blancs: only white grape varieties with white juice (chardonnay and aligoté).

Blanc de noirs: only black grape varieties with white juice (pinot noir and gamay).

Vintage: only wines from a single year (no reserve wines).

Tirage (bottling).

The blend of wine and tirage liqueur is bottled and corked with an iron cap.

Our cellars – 16 million bottles sleep before your very eyes.

Ageing cellars: This is where our famous bubbles are created, thanks to the work of the yeast. Bottles are kept here for a minimum of 12 months.

The transfer

Two robots transfer the bottles to a new crate, this time with the bottlenecks facing in the same direction, to prepare them for the next stage: riddling.

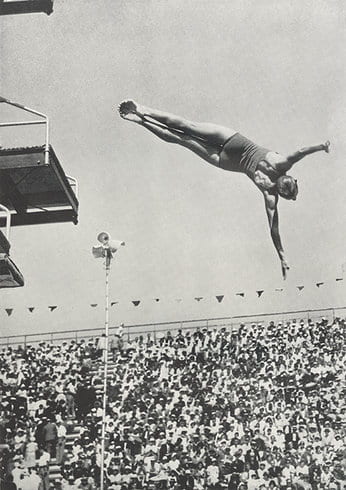

Stirring

The aim is to gather the deposit in the neck so that it can be extracted from the bottle.

The combination of bottle rotation and a very gradual tilting movement brings the bottles from horizontal to vertical position, neck down (this takes about 3 days). The yeast deposit is thus concentrated on the metal cap.

Disgorging and final corking.

The necks (bottle still upside down) are immersed in a liquid coolant at ?25°.[.] An ice cube forms inside the neck, trapping the yeast deposit. The bottles are then turned upside down and tilted at 45° to pass through a “disgorger”, which removes the capsule.[]. Under the effect of pressure, the ice cube containing the deposit is immediately expelled. The liqueur d’expédition (wine + sugar) is then added. The sugar content of this liqueur determines whether our Crémant de Bourgogne is brut, dry or demi-sec. Without delay, the bottles are transferred to the corking machine, where the final cork is placed, followed by the metal wirehood. The bottles are then washed and dried.

Dressing and boxing.

Last workshop before tasting: our bottles are dressed in their finest finery. A continuous parade of bottles is followed by the fitting of caps and labels, and then the boxing of the bottles, creating a fascinating spectacle.

Tasting area (free admission)

20 Crémants de Bourgogne to discover.

Last step: find the Crémant de Bourgogne you love. Taste a selection of wines from our 30 Crémants de Bourgogne, in the friendly atmosphere of our boutique.